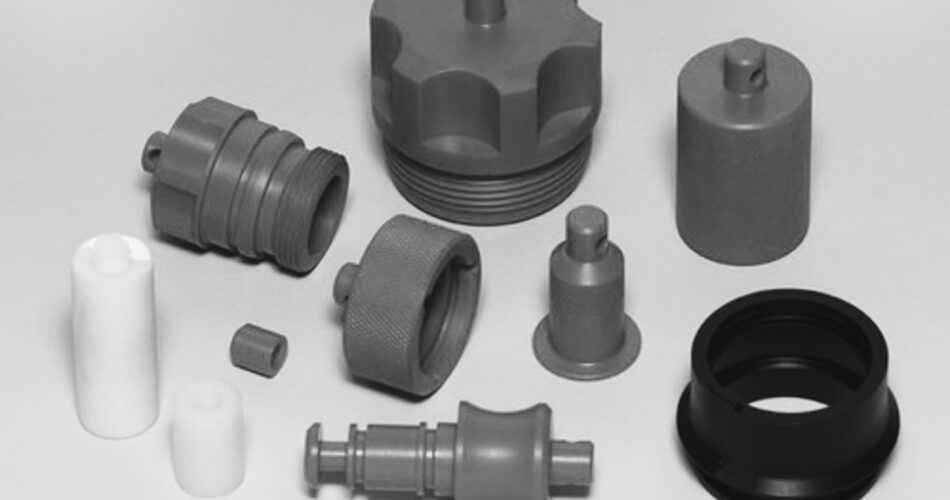

From the smartphone in your pocket to the lifesaving medical device in an operating room, plastic moulded products remain the silent enablers of 21stcentury life. They combine light weight, complex geometry, tight tolerances and costeffective scale in a way few other materials can match.

Yet the real power of plastic today lies in how it is moulded, which materials are selected, and which partner turns design intent into reliable parts. That’s where Plast Tech Engineering—with 25 years of plastic injection experience, inhouse tooling, ISO 9001:2015 quality systems and a growing cleanenergy footprint—steps in.

1. Plastic Injection Moulding

What is the plastic injection moulding process? In simple terms, plastic pellets (thermoplastics or thermosets) are melted, injected at high pressure into a precision mould, cooled and ejected as finished parts. It’s ideal for lowvolume prototyping, highvolume production, and everything in between.

Benefits of injection moulding for small parts

| Benefit | Why it matters |

| Micronlevel accuracy | Critical in electronics & medical devices |

| Repeatability | Millions of identical parts, minimal scrap |

| Material variety | From FDAapproved resins to hightemperature PEEK |

| Cost per unit | Drops sharply as volumes rise |

2. Beyond Standard: Key Plastic Moulding Techniques

| Technique | Best for | Difference between injection & the alternative |

| Thermoplastic moulding | Recyclable products, automotive trim | Melts and remelts; broad resin palette |

| Thermoset moulding | Highheat electrical parts | Cures irreversibly; exceptional dimensional stability |

| Insert moulding | Threads, metal pins, electronics | Places metal/plastic inserts into the mould before injection |

| Over Moulding | Softtouch grips, seals | Adds a second material layer over a rigid substrate |

| Blow moulding | Hollow bottles & tanks | Uses air to inflate molten plastic inside a cavity |

Choosing the right plastic moulding technique for your product depends on geometry, volume, regulatory demands, and target cost. Plast Tech’s engineering team can run tradeoff simulations before the first tool is cut.

3. Materials Matter: From Commodity Resins to Engineering Plastics

-

- Hightemperature resistant plastic materials – PEEK, PEI, PPS for underhood and aerospace parts

-

- Clear plastic moulding for optical applications – PC & PMMA with low haze

-

- FDAapproved plastics for medical devices – USP Class VI grades of PP, HDPE, TPE

-

- Recycled plastic product manufacturing – PCRABS, rPET for sustainable packaging

-

- UVresistant plastic outdoor products – ASA, UVstabilised PP for garden equipment

Need help choosing the right plastic resin type? Plast Tech maintains material data sheets and performs trial runs so designers can validate aesthetics and performance early.

4. Design for Mouldability: Turning CAD into Reality

How to design plastic parts for injection moulding

-

- Uniform wall thickness – minimises sink marks & warpage

-

- Draft angles – 0.5–2° for easy ejection

-

- Rounded corners & ribs – strength without stress risers

-

- Proper gate location – balanced flow, fewer weld lines

-

- Vent & cooling layout – cycles faster, lowers cost

Additive rapid prototyping for insertmoulded parts or lowvolume plastic moulding services bridge the gap between CAD and mass production, reducing overall timetomarket.

5. Common Plastic Moulding Defects—and Plast Tech Solutions

| Defect | Root cause | Plast Tech fix |

| Short shot | Insufficient fill | Balanced runner design, higher shot size |

| Flash | Excessive pressure | Tight tool tolerances, clamping optimisation |

| Sink marks | Thick ribs or bosses | Corecavity tweaks, packing pressure control |

| Burn marks | Trapped air | Venting redesign, process tuning |

Continuous Kaizen, inhouse mould maintenance, and scientific moulding practices keep defects near zero.

6. Sector Spotlights: Where Plastic Moulded Products Shine

-

- Automotive dashboards & HVAC louvers – vibrationresistant engineering plastics moulding

-

- Medicalgrade plastic components – ISOclass cleanroom, biocompatible resins, validated traceability

-

- IoT & consumer electronics enclosures – EMIshielded housings, snapfits, decorative overmoulds

-

- Sustainable plastic packaging – lightweight designs, PCR resins, closedloop recycling

-

- Industrial machinery handles & gears – glassfilled nylon for high torque

7. Cost & Sustainability: Getting More from Every Shot

-

- Cost of custom plastic moulding per unit falls via multicavity tools, family moulds and automated insert loading.

-

- Allelectric presses at Plast Tech save >17 % energy and cut CO₂ (see Energy Independence post).

-

- Plans to reach 30–40 % solar energy by 2026 reinforce our commitment to green manufacturing.

8. Why Plast Tech Is Your Ideal Plastic Manufacturing Partner

-

- Endtoend services – plastic mould design, tooling, moulded plastic components, secondary finishing.

-

- Domain expertise – automotive, medical, electrical, industrial, consumer.

-

- Quality first – ISO 9001:2015, IATF 16949 AUTOMOTIVE QUALITY SYSTEMS.

-

- ISO14001:2015 – Certified for maintaining the international standard for Environmental Management Systems.

-

- ISO 45001 – certified for maintaining the international standard for Occupational Heath and Safety management systems.

-

- Scalable capacity – from rapid prototyping to millions of parts/month.

-

- Location advantage – Chennai, India- Automotive capital of India: costcompetitive, exportready logistics.

9.Metal to Plastic Conversion:

One of the most interesting and talked about points by global OEMs is the process of converting metal parts to plastic. Plast Tech has been going beyond the stereotypes and helping customers solve some major challenges. One such attribute has been providing customer the solution of moving from metal to the use of high performance thermoplastics which provide the following benefits:

-

- Weight Reduction- Plastics are typically 50–80% lighter than metals, which can reduce shipping costs, improve fuel efficiency (in vehicles), and make products easier to handle.

For example: Nylon Radiator cap (vehicle under-hood cooling systems) as compared to a Stainless Steel or Zinc-plated steel.

- Weight Reduction- Plastics are typically 50–80% lighter than metals, which can reduce shipping costs, improve fuel efficiency (in vehicles), and make products easier to handle.

-

- Cost Efficiency – Lower material cost in many cases.

-

- Fewer manufacturing steps – Injection moulding can produce complex shapes in one operation, eliminating machining or assembly steps needed for metals.

-

- Corrosion Resistance – Plastics are naturally resistant to rust, oxidation, and chemical attack, making them ideal for outdoor, marine, or chemical environments.

-

- Design Flexibility – Injection moulding and other processes allow complex geometries, integrated features (threads, locks, hinges, clips), and decorative textures directly in the part.

-

- Performance Enhancement – Engineering plastics can be reinforced with glass, carbon, or minerals to match or exceed the strength of metals while retaining low weight.

-

- Better impact resistance and vibration damping.

-

- Electrical Properties – Plastics are natural electrical insulators — beneficial for electrical, electronic, and high-voltage applications without extra coatings.

For Example: The use of PC (polycarbonate) to injection mould housings, circuit bodies, conduits for various electrical and electronic applications.

- Electrical Properties – Plastics are natural electrical insulators — beneficial for electrical, electronic, and high-voltage applications without extra coatings.

-

- Lower Assembly Requirements – Multi-part metal assemblies can be combined into a single moulded plastic part, reducing fasteners, joints, and leak points.

-

- Noise Reduction – Plastics can reduce noise, vibration, and harshness (NVH) compared to metals.

-

- Enhanced Aesthetics – Wide range of colours, finishes, and surface textures without secondary painting or plating.

-

- Sustainability Opportunities – Many plastics can be recycled or produced from bio-based sources, reducing environmental footprint.

Need custom plastic moulding or plastic part fabrication? Talk to us about contract plastic injection moulding that aligns with your timelines, budget, and compliance goals.

Get Started

Ready to turn innovation into reality? Contact Plast Tech Engineering today for a free designformouldability review and discover how our plastic moulded products can elevate your next project.

No Comments