Precision Engineering

Crafting

Excellence with

Every Component

Precision Engineering Crafting Excellence with Every Component

At Plast Tech, we ensure every component is precisely designed, fabricated, machined, and quality-checked to meet customer requirements.

At Plast Tech, we ensure every component is precisely designed, moulded, machined, and quality-checked to meet customer requirements.

12+

Industries

Served

12+

Industries Served

30Mn+

Parts shipped

Globally

30Mn+

Parts shipped Globally

3-5%

Average Cost

reduced

3-5%

Average Cost reduced

1500+

Products

Developed

1500+

Products Developed

20+

Engineering

Plastics Expertise

20+

Engineering Plastics Expertise

80+

Other Speciality

Polymers

80+

Other Speciality Polymers

Esteemed Clients

Capabilities

With over 25 years of industry expertise, Plast Tech Engineering offers end-to-end solutions in injection moulding, mould making, new product development, and precision machining. Backed by strong in-house tooling, advanced production infrastructure, and ISO 9001:2015-certified quality systems, we consistently deliver high-performance plastic components for critical applications across the automotive, electrical, medical, and industrial sectors.

With over 25 years of industry expertise, Plast Tech Engineering offers end-to-end solutions in injection moulding, mould making, new product development, and precision machining. Backed by strong in-house tooling, advanced production infrastructure, and ISO 9001:2015-certified quality systems, we consistently deliver high-performance plastic components for critical applications across automotive, electrical, medical, and industrial sectors.

INJECTION MOULDING

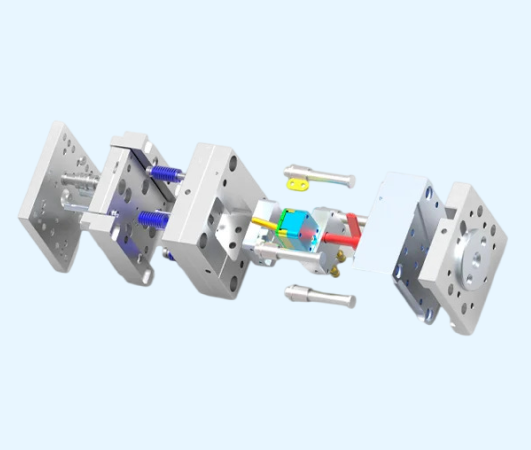

With over 25 years of expertise in plastic injection moulding and 50+ Man years in injection mould making. We specialize in manufacturing critical engineering plastic components with precision and reliability.

Mould Making Support

Plast Tech goes the extra mile by offering plastic injection mould making capabilities. While some customers provide part drawings and mould designs, some need support with expert mould design.

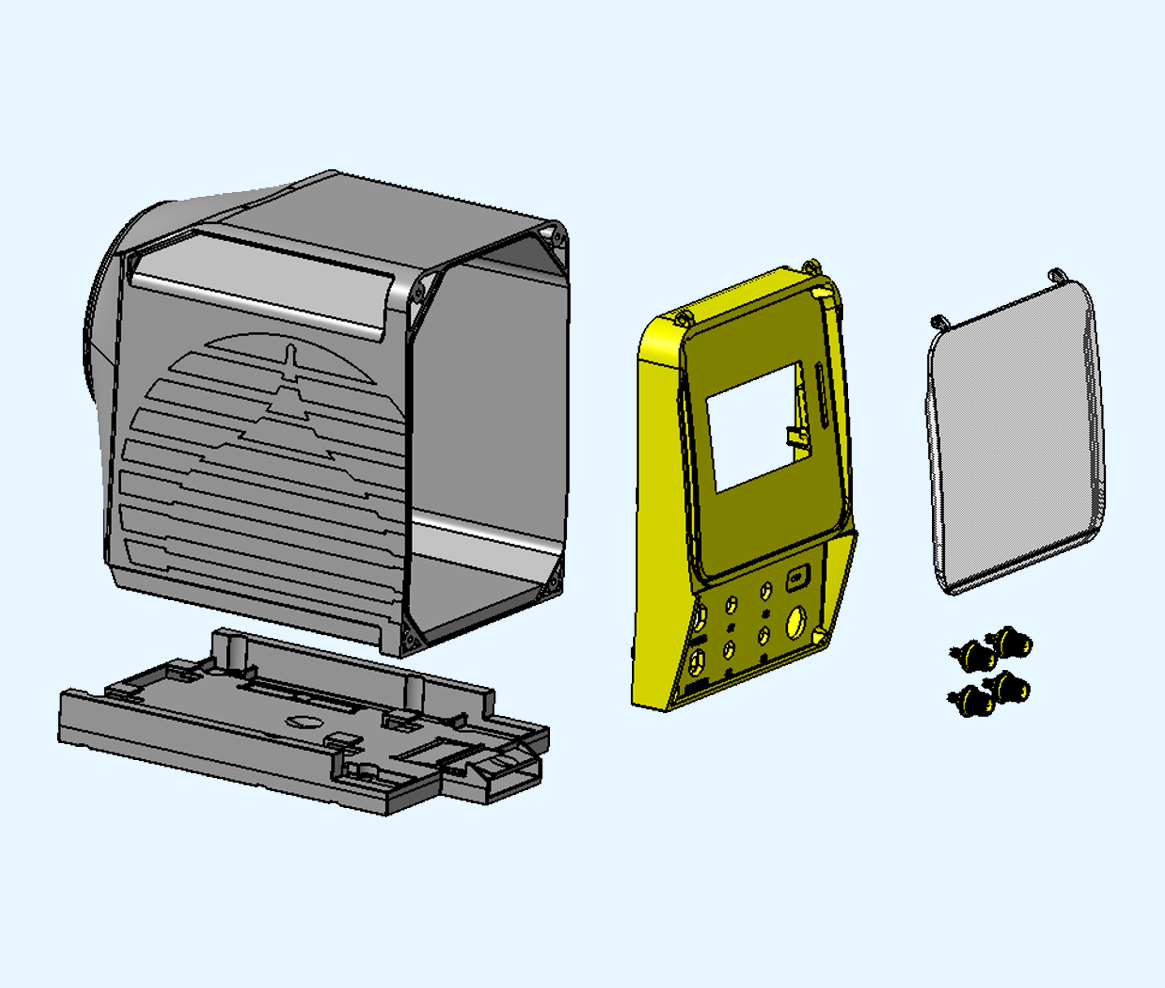

New Product Development

Plast Tech has refined its approach over 25 years by offering customers comprehensive in-house NPD (New Product Development) support. Backed by a dedicated team of design professionals and tooling experts, we deliver complete end-to-end solutions tailored to each product's application and functionality.

Sustainability

Efficient Operations

Our all-electric injection moulding machines have helped us reduce power consumption by up to 17–18%. More importantly, we are able to achieve better yield and greater consistency in product quality.

Efficient Operations

We are working to build a fully solar-powered manufacturing and tool maintenance centre by the end of 2026, aiming to create a smaller environmental footprint. We are ISO 14001 certified, ensuring environmentally friendly working conditions and low-impact manufacturing practices.

Eco-Friendly Facility

We are working to build a fully solar-powered manufacturing and tool maintenance centre by the end of 2026, aiming to create a smaller environmental footprint. We are ISO 14001 certified, ensuring environmentally friendly working conditions and low-impact manufacturing practices.

Eco-Friendly Facility

We are working to build a complete solar powered manufacturing and tool-maintenance centre by the end of 2026, whereby we are able to create a smaller environmental footprint. We are ISO 14001 certified, ensuring our working conditions to be environment friendly and ensuring low environment impacting methods.

Continual Improvement

Plast Tech Engineering adopts a

culture of Kaizen (continuous

improvement) to enhance

safety, quality, and efficiency.

Regular internal audits,

management reviews, and

customer feedback mechanisms

drive our pursuit of operational

excellence.

Continual Improvement

Plast Tech Engineering adopts a culture of Kaizen (continuous improvement) to enhance safety, quality, and efficiency. Regular internal audits, management reviews, and customer feedback mechanisms drive our pursuit of operational excellence.

Our Mission

To embrace a commitment to satisfying the needs of our customers by delivering high-quality products and services on time, with competitive pricing and long-term, consistent value.

Our Vision

To be the first choice for our customers when selecting a world-class manufacturer of plastic parts, assemblies, and products — and a trusted provider of related technical services.

Awards

-

Best Supplier of the Year 2021-2022

Awarded by TVS Sundaram Fasteners Limited (Radiator Caps & Assembly Division). -

Best Green Channel Supplier

Awarded by Synergy Global Sourcing at the Collaborative Supplier Meet, 2023. -

Best Practices

Awarded by Synergy Global Sourcing at the Collaborative Supplier Meet, 2023. -

Excellence in Delivery

Awarded by TVS Sundaram Fasteners Limited (Radiator Caps & Assembly Division), 2021. -

Star Green Channel Partner

Awarded by Synergy Global Sourcing at the Manufacturing Partnership Meet, 2025. -

Extraordinary Support

Awarded by Synergy Global Sourcing at the Manufacturing Partnership Meet, 2025. -

Best in Class Practices

Awarded by Synergy Global Sourcing at the Manufacturing Partnership Meet, 2025.

-

|| Prize in the Small-Scale Category

Awarded by ABK AOTS DOSOKAI in the year 2014. -

Continual Improvement

Awarded by TVS Sundaram Fasteners Limited(Radiator Caps & Assembly Division), 2016-2017.

Awarded by TVS Sundaram Fasteners Limited (Radiator Caps & Assembly Division), 2017-2018. -

Gold Award in the Small-Scale Category

Awarded by ABK AOTS DOSOKAI in the year 2016. -

Best Performance

Awarded by Synergy Global Sourcing in 2017. -

Paver Block Project

Awarded by the Rotary Club of Madras, 2021.

awarded by the Rotary Club of Madras, 2023. -

Installation of Dialysis Machine

Awarded by the Rotary Club of Madras, 2017. -

Awarded for 5S Excellence

Recognized for outstanding in-plant 5S practices.

Contact us Form

Whether you have a query, need a quote, or want to explore a collaboration — drop us a message. Our team will get back to you shortly.