Capabilities

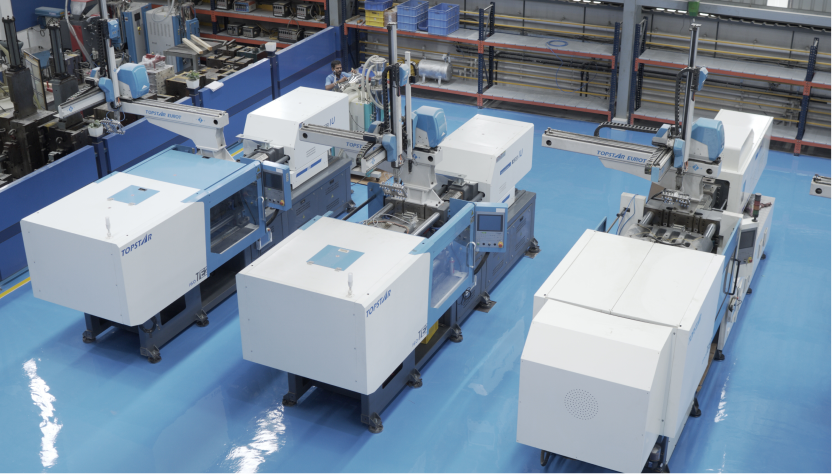

Injection Moulding

With over 25 years of expertise in plastic injection moulding and 50+ man-years in mould making, we specialize in producing critical engineering plastic components with exceptional precision and dependability. Our in-depth industry knowledge, robust in-house tooling, and advanced production infrastructure enable us to deliver high-performance parts for demanding applications across the automotive, electrical, medical, and industrial sectors. Quality, innovation, and engineering excellence are at the core of everything we do.

With over 25 years of expertise in plastic injection moulding and 50+ Man years in injection mould making. We specialize in manufacturing critical engineering plastic components with precision and reliability. Our deep industry knowledge, in-house tooling, and advanced production capabilities enable us to deliver high-performance parts for demanding applications across automotive, electrical, medical, and industrial sectors. Quality, innovation, and engineering excellence are at the core of everything we do.

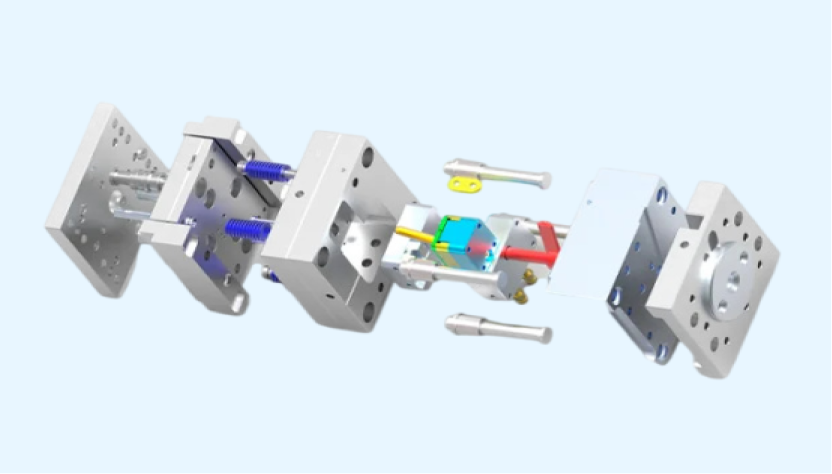

Mould Making

Support

Mould Making Support

At Plast Tech, we go beyond manufacturing by offering expert plastic injection mould making capabilities. While some clients supply part drawings and mould designs, others rely on our expertise for end-to-end mould design and development. Collaborating closely with our authorized tooling vendors, we deliver high-precision single- and multi-cavity moulds—ensuring quality, efficiency, and faster turnaround for all your injection moulding requirements.

With over 25 years of expertise in plastic injection moulding and 50+ Man years in injection mould making. We specialize in manufacturing critical engineering plastic components with precision and reliability.Working closely with our authorised vendors, we deliver high-precision single- and multi-cavity moulds, ensuring quality, efficiency, and faster turnaround for all injection moulding needs.

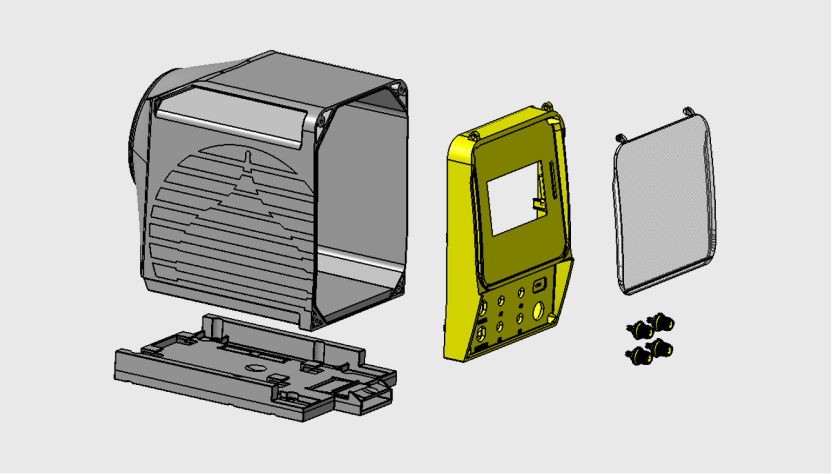

New Product

Development

New Product Development

Plast Tech has refined its approach over 25 years by offering customers comprehensive in-house New Product Development (NPD) support. Backed by a dedicated team of design professionals and tooling experts, we deliver complete end-to-end solutions tailored to each product’s application and functionality. From complex mould design and part conceptualization to precision machining of critical components, we ensure every customer specification is met with accuracy and excellence.

Plast Tech has refined its approach over 25 years by offering customers comprehensive in-house NPD (New Product Development) support. Backed by a dedicated team of design professionals and tooling experts, we deliver complete end-to-end solutions tailored to each product's application and functionality. From complex mould design and part conceptualization to precision machining of critical components, we ensure every customer specification is met with accuracy and excellence.

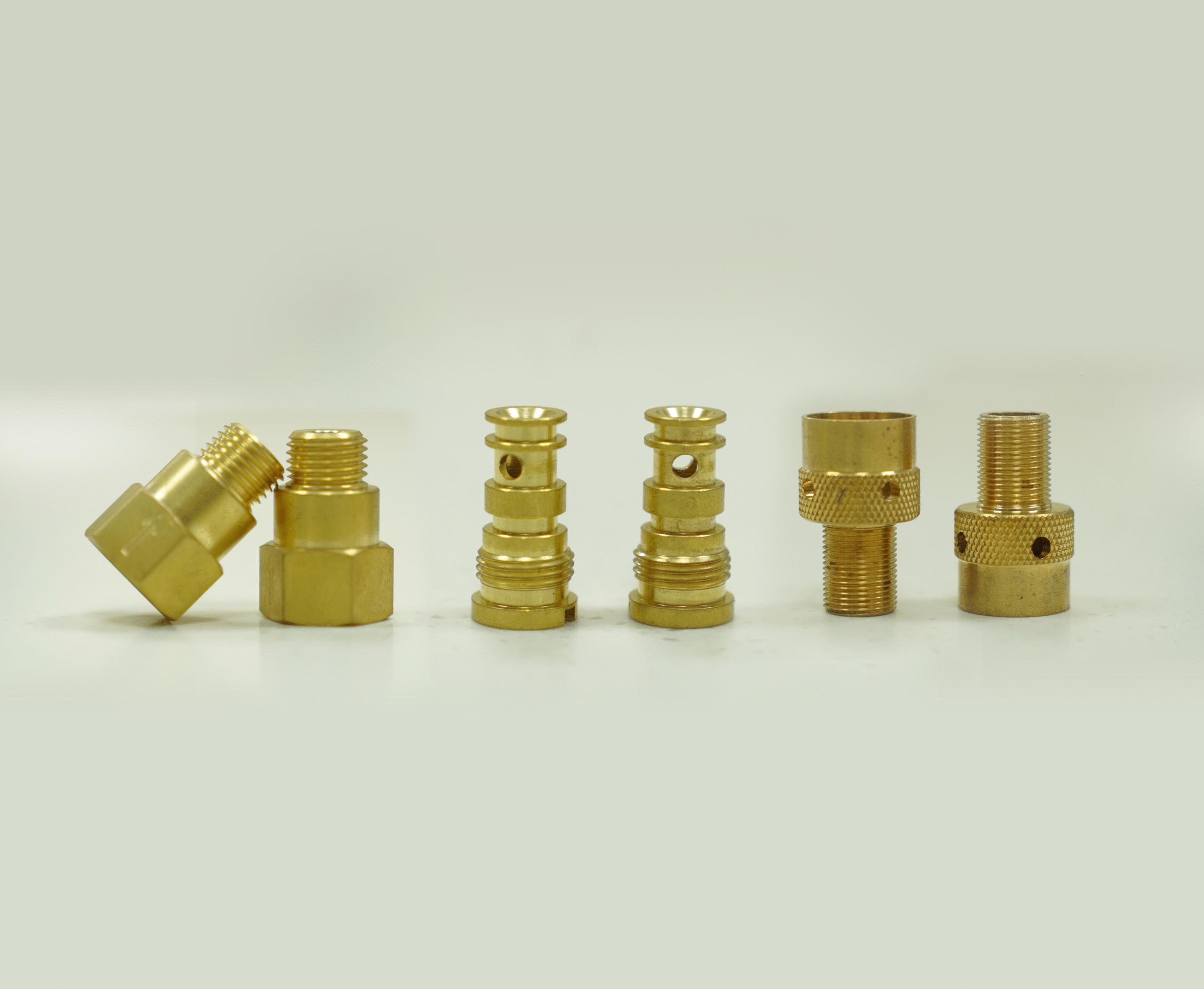

Precision Machining

With growing industry demands, increasing expectations from global OEMs, and stringent dimensional tolerances, Plast Tech has consistently met and exceeded industry standards. Our in-house machining centre, equipped with state-of-the-art CNC and VMC machines, enables us to deliver parts with up to 98% dimensional accuracy, ensuring both precision and reliability in every component.

With growing industry demands, increasing expectations from global OEMs, and stringent dimensional tolerances, Plast Tech has consistently met and exceeded industry standards. Our in-house machining centre, equipped with state-of-the-art CNC and VMC machines, enables us to deliver parts with up to 98%dimensional accuracy, ensuring precision and reliability in every component.

Quality Management

At Plast Tech, we thrive on one core principle: “Never compromise on quality.” Over the years, our unwavering commitment to excellence has earned us strong credibility in the global market for our Quality Management Systems. While we are proud to be ISO 9001:2015 certified, our founders have always believed that true quality goes beyond certifications. From Day One, they established strict parameters to ensure that our facility operations, machinery maintenance, and management systems consistently meet world-class standards. Every component developed at Plast Tech undergoes thorough inspection by our dedicated in-house quality team. Equipped with state-of-the-art inspection equipment, our team ensures that no part leaves the facility without meeting customer-defined quality benchmarks—giving us a distinct competitive edge.

At Plast Tech, we thrive on one core principle: “Never compromise on quality.” Over the years, our unwavering commitment to excellence has earned us strong credibility in the global market for our Quality Management Systems. While we are proud to be ISO 9001:2015 certified, our founders have always believed that true quality goes beyond certifications. From Day 1, they established strict parameters to ensure that our facility operations, machinery maintenance, and management systems consistently meet world-class standards. Every component developed at Plast Tech undergoes thorough inspection by our dedicated in-house quality team. Equipped with state-of-the-art inspection equipment, our team ensures that no part leaves our facility without meeting quality benchmarks as set by the customer - giving us a distinct competitive edge.

Mould Maintenance

In the words of our founder: “Mould making and maintenance lie at the heart of our operations.” At Plast Tech, we’ve built a legacy around mould conceptualization, design, implementation, and precision setting—ensuring that every component produced is identical in detail. We manage between 150 to 200 moulds annually, with processes designed to ensure every running mould undergoes regular inspection and maintenance. This proactive approach minimizes production stoppages and helps us consistently meet customer timelines. We also maintain a robust inventory of accessories and tooling equipment, ensuring zero downtime and on-track production schedules.

In the words of our founder: “Mould making and maintenance lie at the heart of our operations.” At Plast Tech, we have built a legacy around mould conceptualization, design, implementation, and precision setting—ensuring that every component produced from a mould is identical in every detail. We manage between 150 to 200 moulds annually, with processes designed to ensure that every running mould undergoes thorough inspection and regular maintenance. This proactive approach minimizes production stoppages and helps us consistently deliver the best lead times to our customers. Additionally, we maintain a robust inventory of accessories and tooling equipment, allowing us to avoid any downtime and keep production schedules on track.

Supply Chain

Management

Supply Chain Management

Our Supply Chain Management (SCM) system encompasses every stage—from project feasibility and procurement planning to supplier management and audits.

This includes the full production lifecycle:

PPAP (Production Part Approval Process), production scheduling, manufacturing, quality inspection, packaging, and delivery—culminating in final client approval and quality clearance.

With global presence and local sourcing capabilities, we reduce lead times while maintaining a strategic market edge. Our SCM team is dedicated to ensuring:

• Reliable sourcing

• Flexible planning

• Cost-efficiency

• Top-tier quality and packaging

• Customer satisfaction at every level

Our job isn't done until we receive final quality approval from the customer’s team—because for us, success means customer delight.

SCM (Supply Chain Management) is a comprehensive system encompassing every stage from project feasibility and procurement planning to supplier management and audits. It includes the full production lifecycle—PPAP (Production Part Approval Process), production scheduling, manufacturing, quality inspection, packaging, and delivery to customers—culminating in final client approval and quality clearance. With a global presence and local sourcing capabilities, we effectively shorten lead times while maintaining a strategic edge in the market. Our team is dedicated to sustaining a supply chain that is reliable, flexible, and cost-efficient—ensuring top-tier material and product quality, optimized production efficiency, and world-class packaging that guarantees product safety throughout delivery.Our service to the customer is considered complete only once we receive quality approval feedback for each part from their Quality team after delivery. Ultimately, it’s all about achieving customer delight.

Additional Capabilities

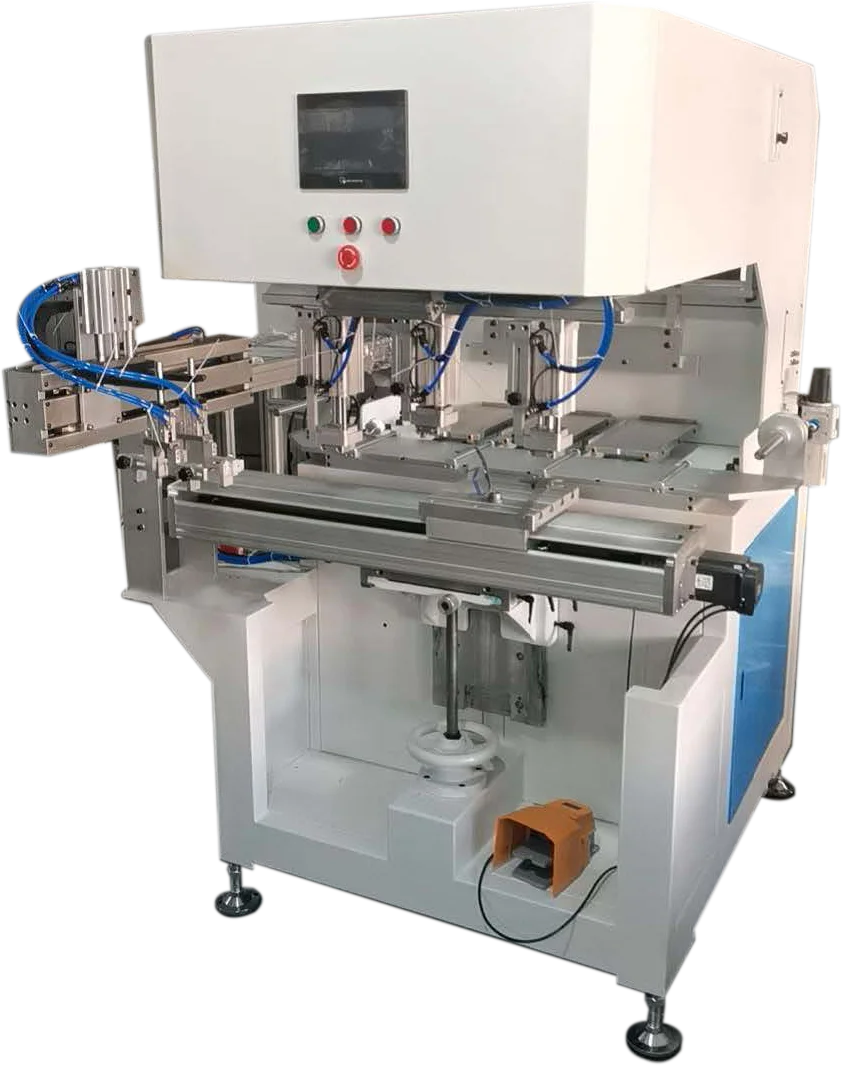

Pad Printing

At Plast Tech, we continue to enhance our end-to-end solutions with the addition of an in-house pad printing facility. This capability meets the rising demand for customized printing—including product names, technical specifications, and branding directly on molded parts. It further strengthens our position as a one-stop solution provider and reflects our commitment to innovation and customer-centric service.

At Plast Tech, we continue to enhance our end-to-end solutions with the addition of an in-house pad printing facility. This new capability meets growing demand for customized printing—including product names, technical specs, and branding—directly on molded parts.It strengthens our position as a one-stop solution provider and reflects our commitment to innovation and customer-centric service.

Laser Engraving

To meet evolving industry needs, we’ve added Laser Engraving to our service portfolio. As turnkey partners to global OEMs, adding value is key. Our expanded printing and labelling facility now enables high-precision engraving of logos, part numbers, specifications, and other critical data directly onto components—ensuring durability and accuracy. We continue to go beyond expectations, delivering more than just the essentials.

To meet evolving industry trends, we’ve added Laser Engraving to our service portfolio. As turnkey partners to global OEMs, offering added value is key.Our expanded printing and labeling facility now enables high-precision engraving of logos, part numbers, specs, and critical data directly onto components—ensuring both durability and accuracy.With this, we continue to go beyond expectations, delivering more than just the essentials.

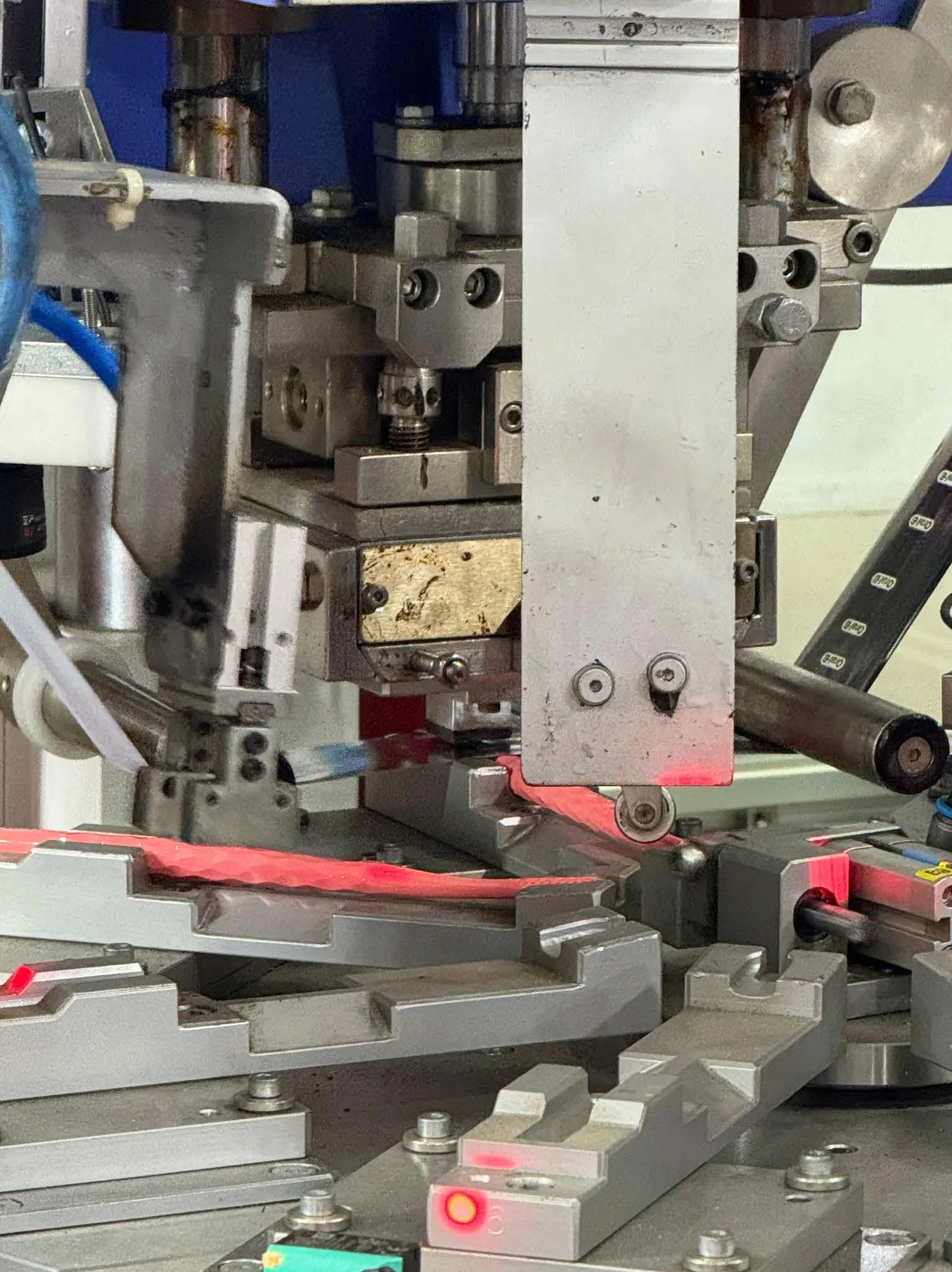

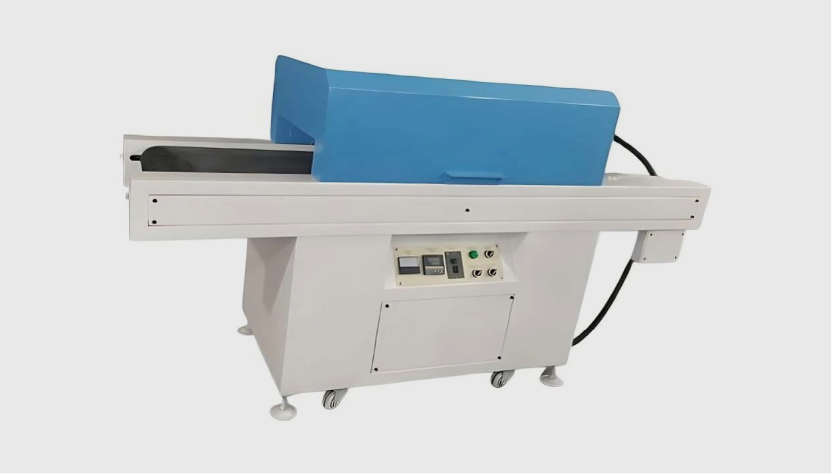

Hot Stamping

Hot stamping is a dry printing process used to apply metallic or pigmented foil onto plastic surfaces using heat and pressure. Widely used in industries such as automotive, cosmetics, electronics, and appliances, it is ideal for branding, decoration, and functional labelling. We’re proud to announce our in-house hot stamping facility as part of the Printing and Labelling Department—offering yet another value-added service to our clients.

Hot stamping on plastic parts is a dry printing process used to apply a metallic or pigmented foil onto a plastic surface using heat and pressure. It’s widely used in industries like automotive, cosmetics, electronics, and appliances for branding, decoration, and functional labeling. We at Plast Tech are proud to announce our in-house hot stamping facility part of the Printing and Labelling Department.